EDINBURG — Santana Textiles, a denim manufacturing company that received $15 million in taxpayer assistance, has long been a point of contention for the Edinburg Economic Development Corporation (EDC), and it most recently became the subject of an EDC video that characterized it as a “bad debt, a bad investment.”

EDC Board president Gilbert Enriquez said in a June Facebook video that the economic incentives the previous board approved for the company left taxpayers vulnerable and at risk for a combined $15 million the EDC dished out to help get the company off the ground.

“Santana has no risk in that 15 million dollars,” Enriquez said in the pre-produced video. “The taxpayer is 100 percent on the hook for those 15 million dollars — regardless if they produce, you know, one yard of denim or five million yards of denim.”

The company has struggled to become fully operational, and to this day it is not. Though it is currently spinning cotton into denim, only 50 percent of its capacity has been installed.

Santana Textiles — which began doing business as Denimburg in 2016 as a marketing gimmick and a nod to the city — is operating at 20 percent of its initial expected capacity and has not come close to the amount of employees it promised to hire.

But perhaps most worrisome to the board, it appears to also have fallen behind on payments to the EDC.

“Right now they are behind on the loans, and they’re not current,” Enriquez said in the video dated June 13. “Of course, the EDC has to be current to the bondholder because if we default, then it ruins our credit standing.”

Santana staff disputed the claims during an interview Friday, but did not delve into specific financial information.

“I’m not on the finance side, but as far as I understand, yeah,” operations manager Claudio J. Motta said when asked if the company was on track with payments to the EDC.

Instead, Motta said he remained confident in the company’s ability to stay afloat, saying it recently switched its focus from selling commodity products to Mexico to instead selling high-end products to U.S.-based companies like Eddie Bauer and Calvin Klein.

The change in vision, coupled with President Trump’s new ‘Made in America’ approach and his international trade policies, have breathed new life into the company.

“We are struggling to keep up the pace,” Motta said. “We are bringing people back.”

HISTORY

Santana Textiles is part of a larger Brazilian company called Grupo Santana. The family-owned business owns five other plants: four in Brazil and one in Argentina.

“The owner’s grandfather, during his wedding, somebody gave him as a present, an old rug-making machine,” said Ivan Salinas, head of human resources. “So that’s how he started. He started making hammocks out of that.”

Mesmerized by the denim-making process, he soon began to manufacture and sell locally in Brazil before turning his attention to the outside world. In 2008, Edinburg became its focus.

The company approached the EDC with a plan to invest $100 million to build a denim-manufacturing plant. Once operational, it would hire 800 employees and yield 1 million cubic meters of fabric per month.

“It was a good business deal,” Enriquez said.

So in order to lure the potential investment, the EDC offered a $5 million loan and 33 acres of land in the city’s North Industrial Park to build the 280,000 square-foot facility.

Santana broke ground in 2011, but, like EDC Board President Gilbert Enriquez said in the video “it took them a lot longer to finish the project and to start operations.”

Santana went through a number of setbacks and did not meet its expectations, forcing it at one point to return more than $800,000 it received in economic incentives from the state through the Texas Enterprise Fund.

“In 2011, we had a pretty big world-wide problem with the cotton price,” Motta said. “It spiked two or three times its regular price.”

According to Monitor archives, the price of cotton peaked at $2.29 per pound as compared to the current price of about 88 cents.

“It had a very big impact on the operations in South America, which was the one funding the construction and installation,” Motta said. “We had to put the project on hold for about three years.”

In 2015, the company once again approached the EDC for help.

“Back in 2015, they weren’t producing what they should have been producing. They had less than 100 jobs that they were occupying,” Enriquez said. “So they needed more capital in order to sustain the amount of money they were paying out, and so they decided to come back to the taxpayers and ask for an additional 10 million dollars so they could continue production.”

Despite being routinely behind on payments, the EDC board at the time approved the $10 million loan. At the time, Santana had only paid down about half-a-million dollars of the original $5 million loan it received. The company was nowhere near its capacity and employed a fraction of the hires it promised.

Along the way, the board also essentially gave up the only leverage it had: the company’s lien.

“So really, we weren’t receiving any job creation, and we weren’t receiving any property tax value because they weren’t where they should have been in the five years, in the original agreement,” Enriquez said. “So it was just a convoluted situation that really, it’s been taking us very long to decipher.”

Today, the company employs 72 workers and has made a total investment of about $50 million.

LEARNING CURVE

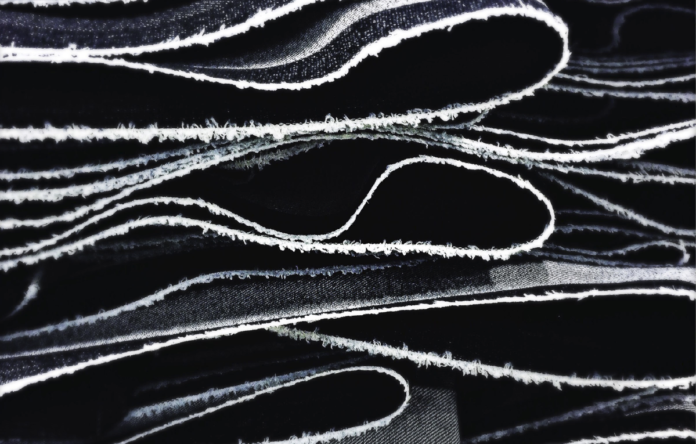

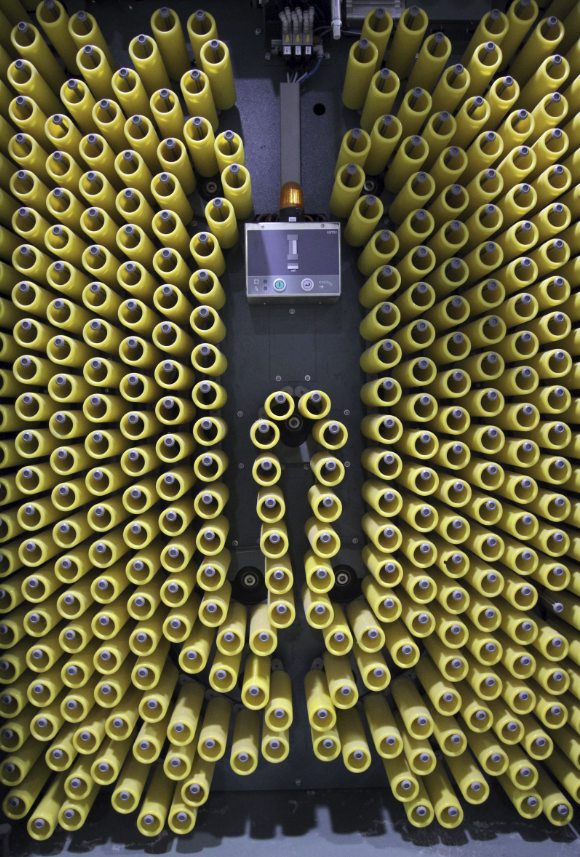

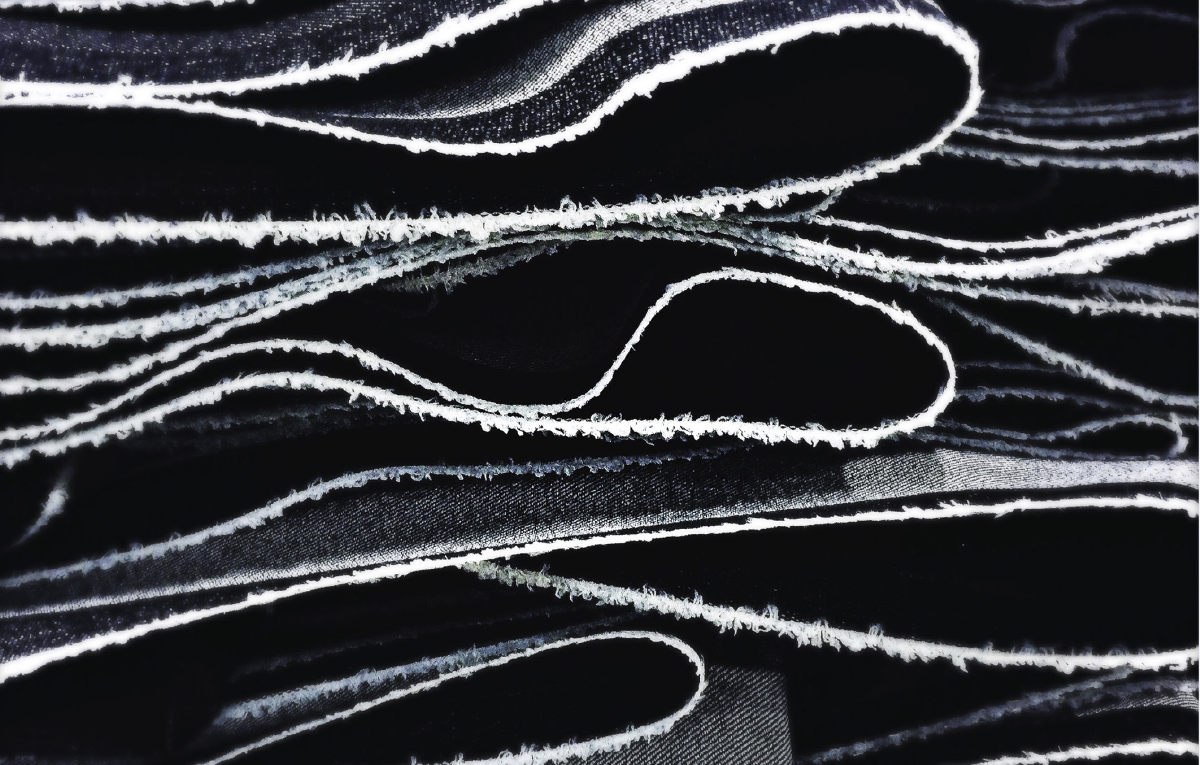

It takes about 20 days for cotton to be cleaned, spun, woven and turned into fabric, and last month, the massive and highly-sophisticated machinery churned out about 100,000 cubic meters of denim.

Motta said the company will produce 200,000 meters this month and hopes to be at 500,000, or 50 percent capacity, by year’s end.

“We spent the first year-and-a-half to two years of operation learning and training our people, and we were focused at that time on more basic products,” he said. “We were competing with Asian products, which is very difficult, very hard to compete against, but now I think we are on the right path with the right products and the right clients.”

The president’s ‘Made in America’ campaign has helped the company find a clientele hungry for U.S.-based goods, and Denimburg is one of two denim-manufacturing plants in the U.S. A third plant was designed to produce denim, but it is currently producing socks and other cotton products.

Most of the denim-producing companies moved overseas in the early 90s, pursuing cheaper labor. Today, about 90 percent of denim comes from outside the U.S.

“We try to get all of the resources from in-house, which is the United States, and we’ve been doing that ever since we started here,” Salinas said. “A lot of people want ‘Made in America’ now, so a lot of people are coming to us, asking us what we can do for them. That’s why we’re starting to get recognized a lot right now, and orders are coming in.”

The company purchases cotton locally and from other parts of Texas.

“I used to say I’m in heaven because the cotton in Argentina is terrible,” Motta said. “But the Texan cotton is wonderful. I’m very happy with it.”

The company names its products to remind clients it was manufactured in America, using names such as Brownsville, Kingsville and Washington for various types of denim. But selling it can be time-consuming and costly.

Denimburg staff began negotiating with Calvin Klein in September and didn’t receive its first order from the fashion industry titan until February. Part of the five-month wait stems from the process of developing the material to the client’s exact specifications, which include texture, color and finishing touches.

Once the company tinkers with the formula, samples are sent out, often times to Europe and Mexico, and they are either given a green-light or sent back for adjustments.

“As you can tell, these guys are bustin’ their hump to make sure we are meeting our customers’ demands,” Salinas said.

The human resources director said the company is currently in the process of hiring more workers and expects to have 100 employees in the coming weeks.

“We are going to continue to surpass all the bad stuff we had in the past and we’re going to keep moving forward,” Salinas said.

And as far as the EDC is concerned, the company declined to address the animosity.

“We’re not trying to get into politics. It’s a family-owned business, privately owned,” Salinas said. “We just want to push forward and keep doing what we’re doing.”